Previously I made a battery-powered temperature and humidity sensor. that sensor worked on a 500mAh Li-ion battery. Then I realized that I didn’t have a lithium-ion battery charger. so I decided to make one.

protection features are the most important part of working with a Li-ion battery. overvoltage can damage the chemical process of the battery, which can damage the life cycle of the cell.

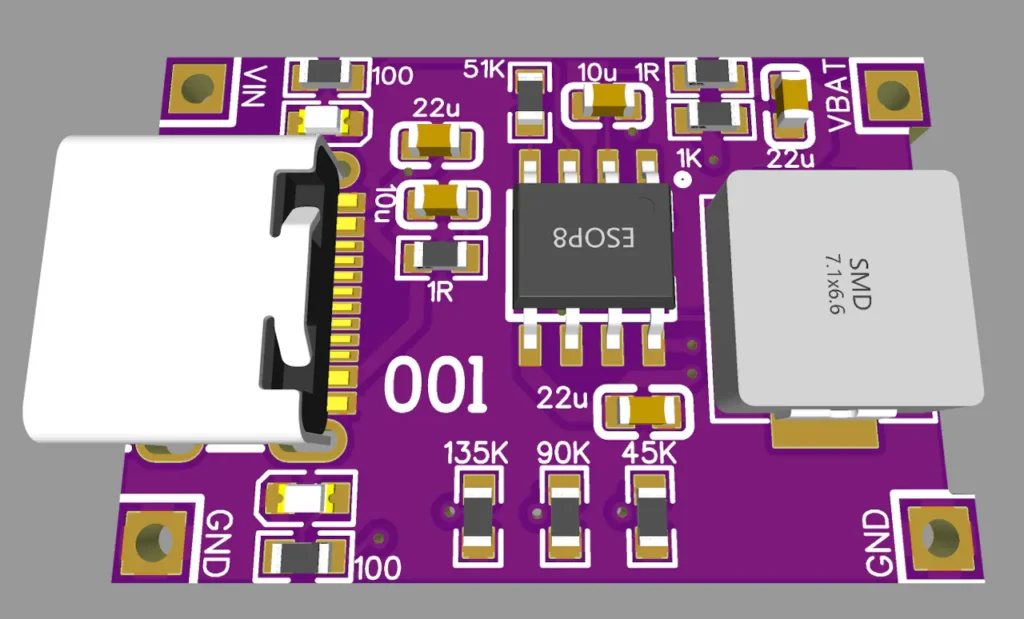

I came here with a new module based on IP2312 and designed by me keeping the max current of 3A in mind. Yes! this board comes with fast charging and protection features and all of them are listed below.

In IP2312 the scenario is better than TP4056 because here every protection feature is included in the IC, so we don’t have to use any extra IC for discharge/charge protection. Why I am focusing on this because this IC has a buck converter section rather than a linear voltage regulation. IP2312 Boost Switching Charge Converter Operating Frequency 750KHz, the maximum charging current is 3A, 5V input, 3.7V/2A conversion. The conversion efficiency is 94%; the charging current can be set through an external resistor. The input voltage of IP2312 is 5V, and the input can intelligently adjust the charging current to prevent the adapter from being pulled.

- Max input voltage: 4.5 to 5.5 volt

- Trickle charging current: 100mA

- Max charging current: 3A

- Nominal Charging current: 2.1A

- Overvoltage protection: Vin > 5.6

- Undervoltage Protection: Vin < 4.5

- Standby Current: 40uA

And it comes with an extra feature of Trickle charging. See how a Li-ion battery charging process works from here. Trickle mode is very important to increase the overall health of the battery, and it is the process of charging the battery when it is over-discharged.

I designed the PCB using Altium Designer. Get a free trial of Altium Designer with 365 and 25% off your purchase: https://www.altium365.com/yt/robocircuits

The PCB was ordered from Seeedstuido. PCB manufacturing and assembly services from Seeed Fusion: https://www.seeedstudio.com/fusion_pcb.html

Then I assembled the PCBs and put them to the test. I soldered a 3.7-volt Lipo Battery to it and plugged it with a wall charger. When charging the battery at full potential very little heat is produced, which satisfies the 94% efficiency of this IC. I also have tested all protection features and all of them are working very normally. It is always recommended to check the output voltage of the board which should be in the range of 4.15-4.22 volts for a Li-ion battery.

The Circuit worked fine and the battery was charging properly. So, we can say battery voltage is constant in this 20-second testing period. With TP4056 the max charging current is 450mA and with TP2312 the same battery charging current is measured nearly 1A. In all, it doubles the charging rate, increases the overall efficiency, and covers almost all protection features.